A national home improvement company found it impossible to keep up with the constant packing and distribution of its branded promotional products and apparel as its network of authorized dealers grew. They had been handling all of these functions internally, but the demand was growing far beyond their ability to keep up. They needed support if they were going to continue to be a trusted source of quality home improvement services.

The Fulfillment Challenge

To focus on the growth of the business, management decided it was best to outsource the warehousing, inventory management, and fulfillment to a company with expertise. They specifically sought a provider experienced in promotional product fulfillment with real-time inventory and 24/7 access to an ordering system. They required a customized order management system (OMS) portal that provided two unique views. They needed to physically transition 100+ SKUs and set up an effective re-stocking program to avoid issues like product surplus or stockouts.

The Fulfillment Solution

There are many different kinds of logistics providers, but Fulco Fulfillment Inc. (FFI) was the perfect fit. Our robust logistics, exceptional inventory management system, top-notch customer service, and branded promotional products web portals were the ideal solution for this home improvement company’s needs.

Managing Inventory: Transition 100+ SKUs

FFI’s management and dedicated client service coordinator took the steps to gain a thorough knowledge of the client’s business. The trained and attentive warehouse team then accurately transitioned the 100+ SKUs into our warehouse in Dover, NJ. The inventory was organized and included a diverse set of products.

- staff uniforms

- promotional giveaway items

- marketing materials

- signage

- everyday brand ware

- prizes

FFI learned the details of their inventory and requirements for packing and shipping. Setting up SKU locations for efficient picking streamlined the fulfillment process for a smooth transition.

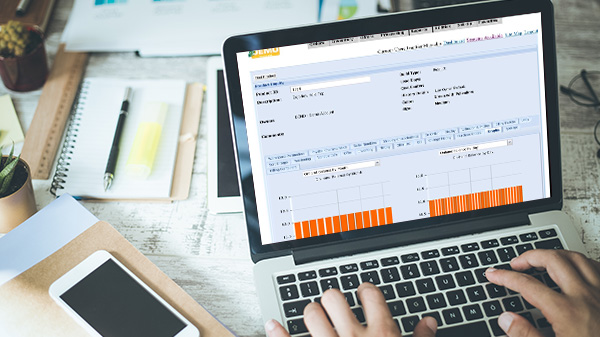

Order Management System

Our flexible order management system platform provides on-demand access. Each pre-registered user was given a login and password to access the portal 24/7. The pre-registered user was then able to view the inventory permitted by their access level:

- Client Management View

- Authorized Dealer View

Order screens are pre-populated based on the login. The managers see all inventory, but the franchise owners have access to limited earmarked inventory. Orders are entered into the order management system and captured with easy, shopping cart functionality. Once an order is placed, the customer receives an email acknowledging that the order has been received. They receive another email when the order ships.

Inquiries done on product details are in real time, and inventory reports can be generated through the portal. Users can keep track of their order’s historical data and package tracking information.

Using barcode technology, FFI accurately tracks and maintains inventory from receipt to inventory movement to picking and shipping. This kind of solid inventory management avoids pitfalls like running out of branded promotional products right before a scheduled tradeshow or convention.

FFI’s OMS also can prioritize orders by selecting a “rush” button, which sends the order directly to the customer service coordinator for priority processing.

Keeping the Inventory Stocked

Maintaining optimal inventory levels is integral to our customer’s success.

Levels are managed in real time to prevent an item from going out of stock. FFI worked with the customer to establish a re-stocking program, assigning a replenishment point to each product, referred to as the understock level. When a product reaches the understock level, an email notification gets sent to our customers, allowing ample time to order replacement inventory. Replenishment is shipped to FFI’s warehouse from the customer’s marketing and promotional products provider and the products are received into inventory for ordering visibility. This process prioritizes meeting customers’ demands, ideally without experiencing stockouts or overstock issues.

Fulco Fulfillment Helps Businesses Grow

With Fulco handling their branded promotional product and apparel fulfillment, our client has been able to triple their network of authorized dealers. Their commitment to quality continuously exceeds the expectations of their customers and they remain a trusted source for quality and reliable home improvement services.

If you’d like to learn how we can help your business grow, give us a call at 973 361 1700 or fill out our contact form.