With the nutraceutical market rapidly growing and actively thriving, the need to fulfill orders through 3PLs is quickly rising in response to consumer demands. Your nutraceutical order fulfillment should be handled by a trusted partner who understands nutraceutical warehousing and inventory control, Amazon FBA prep programs, and nutraceutical direct mailings. It is crucial to team up with a 3PL provider partner with experience in the complexities that may come with nutraceutical fulfillment.

Efficient warehousing, inventory management, and distribution are essential for the success of nutraceutical order fulfillment. These three factors ensure product quality, optimized shipping, and customer satisfaction, which are top priorities for nutraceutical fulfillment.

Warehousing for Nutraceuticals

Warehousing plays a vital role in maintaining the integrity of differing nutraceutical products. A well-organized warehouse with proper temperature and humidity control helps to prevent spoilage, degradation, or contamination, ensuring that each product a customer receives is of high quality.

Inventory Management for Sensitive Timelines

Inventory Management is another critical factor in nutraceutical fulfillment. Due to differing lot numbers, expiration dates, and the shelf life of many supplements, proper inventory tracking is necessary to prevent overstocking or understocking. It is helpful for your 3PL of choice to have a powerful order management system (OMS) with capabilities to track versions and expiration dates of nutraceuticals.

Distribution Efficiency Increases Customer Satisfaction

Efficient distribution impacts the delivery of goods as well as customer satisfaction. Fast and accurate distribution not only enhances customer experience but also builds brand trust, which is essential in the particularly competitive landscape of the nutraceutical industry. Choosing the right 3PL partner to ensure seamless order processing, timely dispatch, and reliable carrier partnerships can be difficult.

The right partner will deliver efficient warehousing, inventory management, and distribution in ways that can elevate your nutraceutical fulfillment.

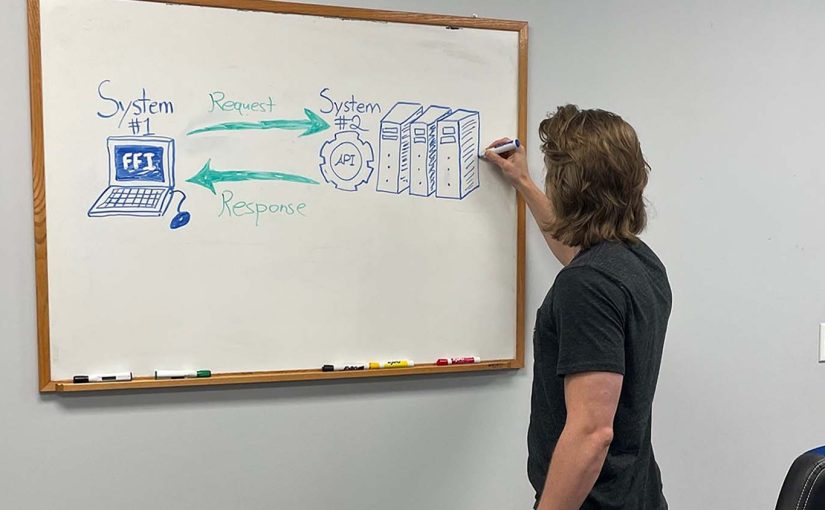

Technology Integration Improves Nutraceutical Fulfillment

The most up-to-date technology integration is essential for optimizing nutraceutical fulfillment, improving efficiency, accuracy, and compliance. Seamless eCommerce integration with platforms such as Shopify, Amazon, and WooCommerce allows clients to automate order processing, reducing manual errors and speeding up the fulfillment process. At FFI, we also provide Fulfillment by Amazon (FBA) services, where we handle the receiving, re-labeling, and preparation of full pallet shipments to ensure compliance with Amazon’s exacting requirements.

Outsourcing to FFI eliminates the time-consuming fulfillment process, allowing you to focus on the growth of your business. By leveraging technology, 3PL providers like FFI help nutraceutical companies improve accuracy, shorten fulfillment times, and enhance overall customer satisfaction.

FFI Offers Nutraceutical Companies Cost Savings and Operational Efficiency

A scalable 3PL partner enables nutraceutical brands to expand seamlessly without logistical constraints. Flexible warehousing options allow businesses to scale storage space based on demand, product launches, or market fluctuations, preventing unnecessary overhead costs. By outsourcing your fulfillment to a trusted 3PL like Fulco Fulfillment, Inc., nutraceutical businesses can focus on growth while maintaining an optimized supply chain. Get in contact with the experts at FFI today to learn more!